The cushions - Products - DUNAPACK®

The DUNAPACK® Air in Place line includes a wide variety of cushion formats designed to meet all protection and packaging needs. The AIP bags come in pre-cut shapes of different sizes to best suit the type of goods, packaging and shipping method. Available in all 3 existing films (high-density polyethylene, polyamide polyethylene, compostable biodegradable TEO and regenerated recycled RIO), the Air in Place cushions come in different thicknesses depending on the material and they offer outstanding targeted performance.

The AIP range has recently been revised to significantly reduce the thickness of all cushion films in order to minimise the consumption of raw materials and plastics, without compromising the level of protection of packaged products.

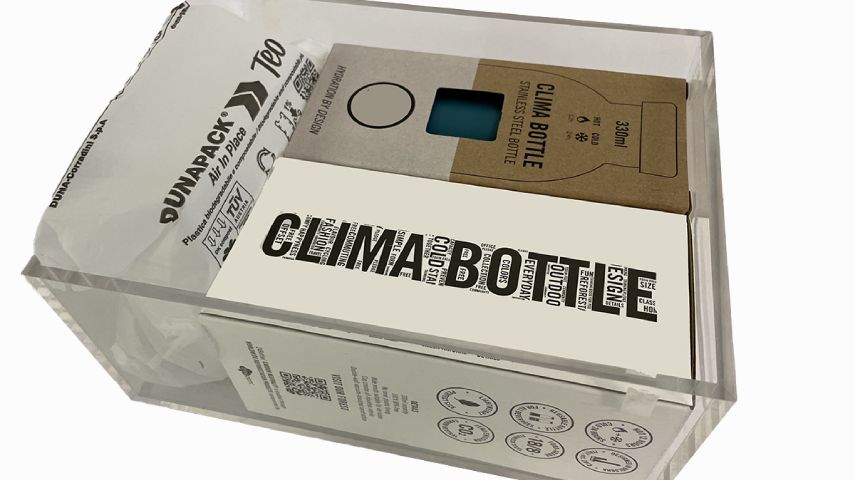

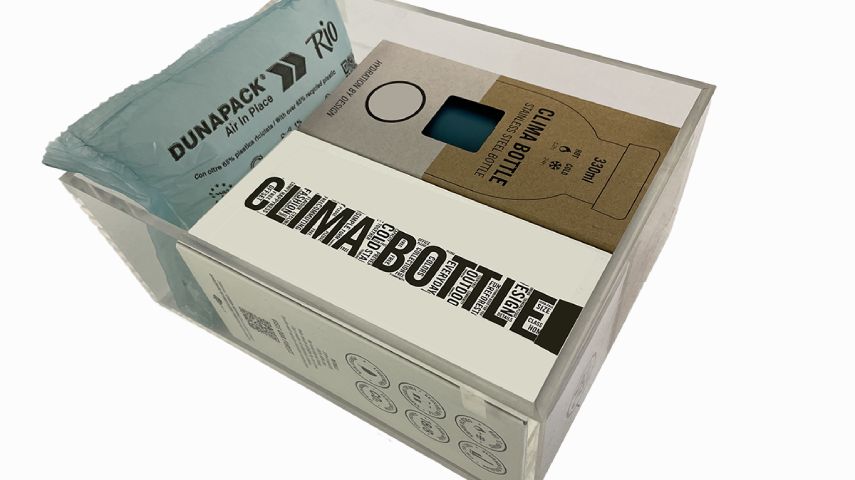

For blocking the products and filling voids inside the box, DUNAPACK® offers various formats, rectangular and square, from 200x110mm to 400x110mm. It is the ideal solution for supporting and protecting goods, whatever the size of the box.

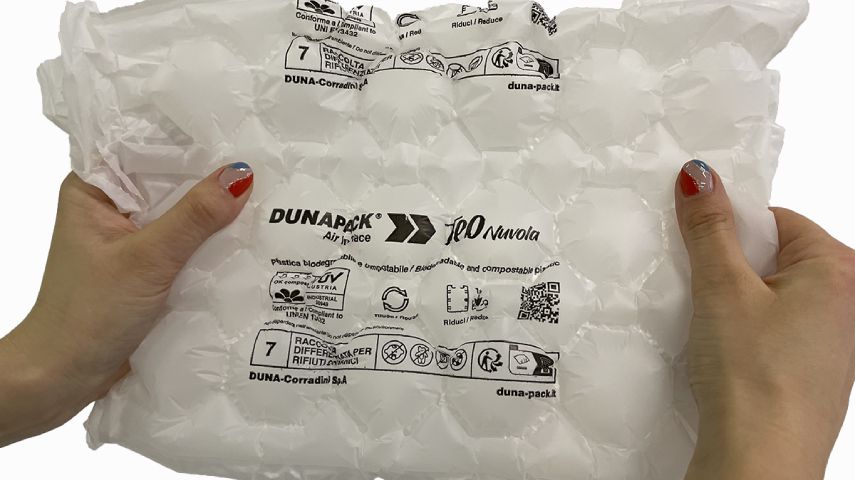

For the protection and wrapping of the most delicate products and for packaging where maximum flexibility is required, DUNAPACK® has developed the new NUVOLA multi-bubble pillow (400x270mm), an efficient alternative to traditional bubblewrap. Featuring an innovative design of staggered interconnected bubbles, the NUVOLA format is designed to maximise the shock-absorbing function, even if the cushion partially deflates. The NUVOLA cushion is available in the compostable TEO and regenerated RIO films, two high-performance and green solutions.

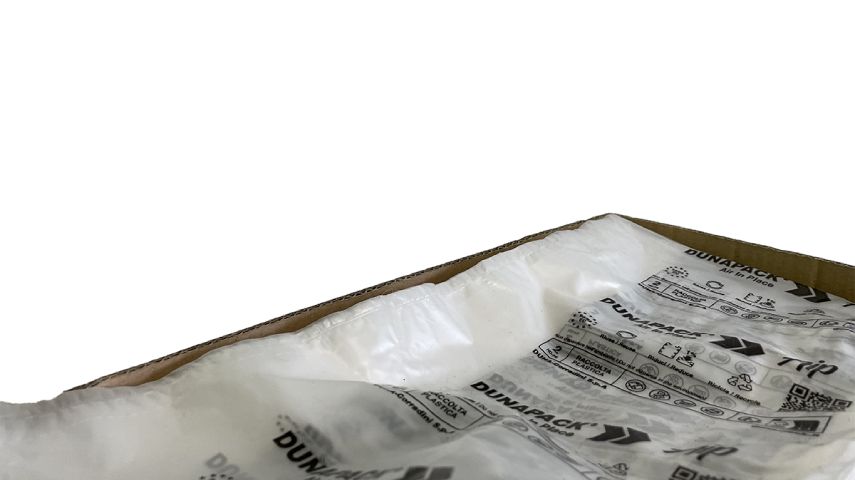

Since 2021, all DUNAPACK® cushions have been supplied in convenient reams of ready-to-inflate film, instead of the traditional coils, for greater efficiency and customer convenience. Reams supply minimises packaging storage costs and internal handling problems and doubles the amount of film per pack, reducing the environmental impact of transport. A box of reams with a volume of only 0.03 m3 produces 8 m3 of cushions!

Compared to the previous coils system, the film reams ensure maximum storage efficiency, stability and cleanliness. The pre-cut, ready-to-inflate cushions stay protected from light, dust and dirt until they are actually used. The ream supply also contributes to reducing machine stress. On the one hand, the cushions are not subjected to strain during start-up in the inflating machine, ensuring perfect integrity and performance, on the other hand the packaging system is simple and noiseless for the benefit of the liveability of the working environment.

| Film name | Material composition | Certifications and sustainability | Thickness | Available sizes |

|---|---|---|---|---|

| AIP | HDPE (Polyethylene high density) | Printing with eco-labelling (Italian Legislative Decree 116/2020) |

22µm |

200x110 200x150 200x200 400x110 |

|

TEO NUVOLA TEO |

PLA+PBAT (compostable and\biodegradable fermented starch + biodegradable co-polyester) | OK COMPOST TÜV INDUSTRIAL UNI EN 13432 Printing with eco-labelling (Italian Legislative Decree 116/2020) |

20µm 25µm |

200x110 200x150 400x270 |

|

RIO NUVOLA RIO |

rLDPE (Polyethylene low density 75% raw material recycled) rLDPE (Polyethylene low density 65% raw material recycled) |

Printing with eco-labelling (Italian Legislative Decree 116/2020) |

19µm 24µm |

200x110 200x150 200x200 400x110 400x270 |

| RIO LIGHT | rHDPE (Polyethylene high density 35% raw material recycled) | Printing with eco-labelling (Italian Legislative Decree 116/2020) | 13µm | 200x200 |